There was a bit of a panic when people started seeing 12VHPWR adapters from Nvidia with melted connectors. Igor's Lab took one apart and concluded that the issue is with potentially breaking solder joints where the wire is soldered to the terminals. This seemed to be a reasonable theory.

Then, Ronaldo Buassali did some pretty crazy testing and couldn't get the adapters to fail. UNLESS he loaded up the cable without the connector being fully inserted into the GPU (or in his case, the ATE).

Later, Gamers Nexus got their hands on some adapters, ran them for a while, and couldn't get any of them to melt. There was, however, a difference in construction between Igor's and GN's cables.

Ronaldo came back with a longer version (director's cut?) that goes more into depth about his testing.

We're still waiting to hear back from Nvidia. When I reached out a few days ago, I was simply told "we're still testing".

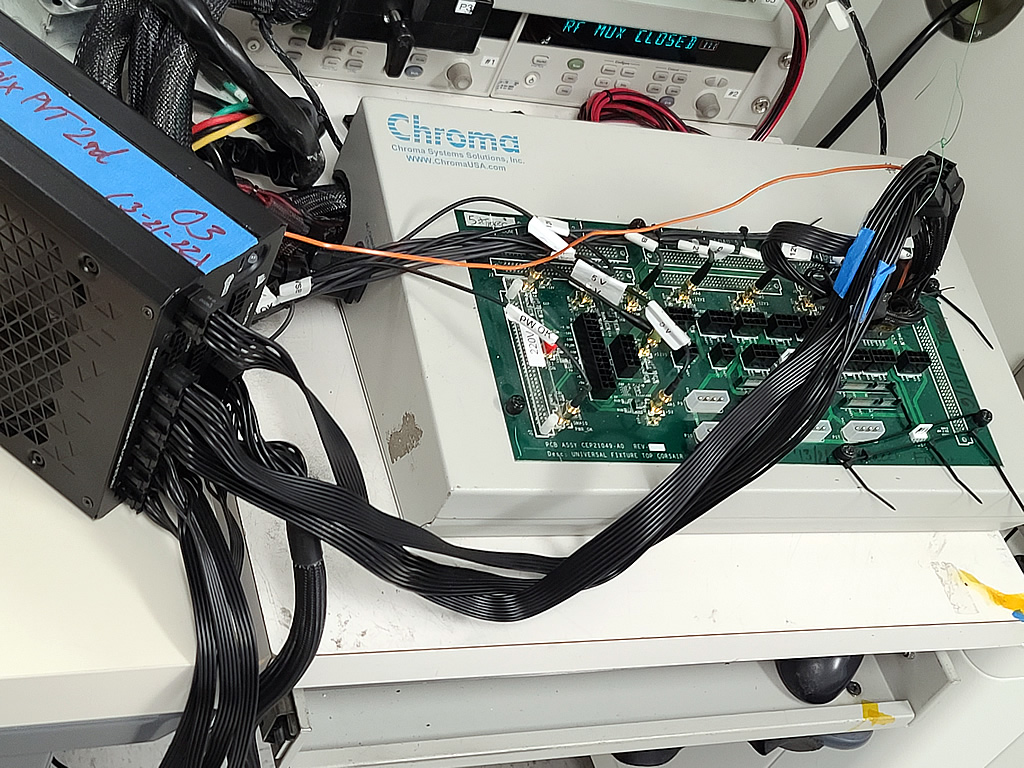

I decided it was my turn to check these too. A few weeks ago, I decided to round up as many Nvidia adapters as I could (big thanks to the guys at Origin for this!). I put them on the ATE and loaded them up and let them ferment for either the entire day, or overnight.

This is the test setup. Just an HX1500i with three PCIe cables going into the Nvidia adapter. A Fluke thermistor is there to take temperatures. The zip-ties are there so I can do < 30mm bends on the cable during testing to see if excessive bending causes damage.

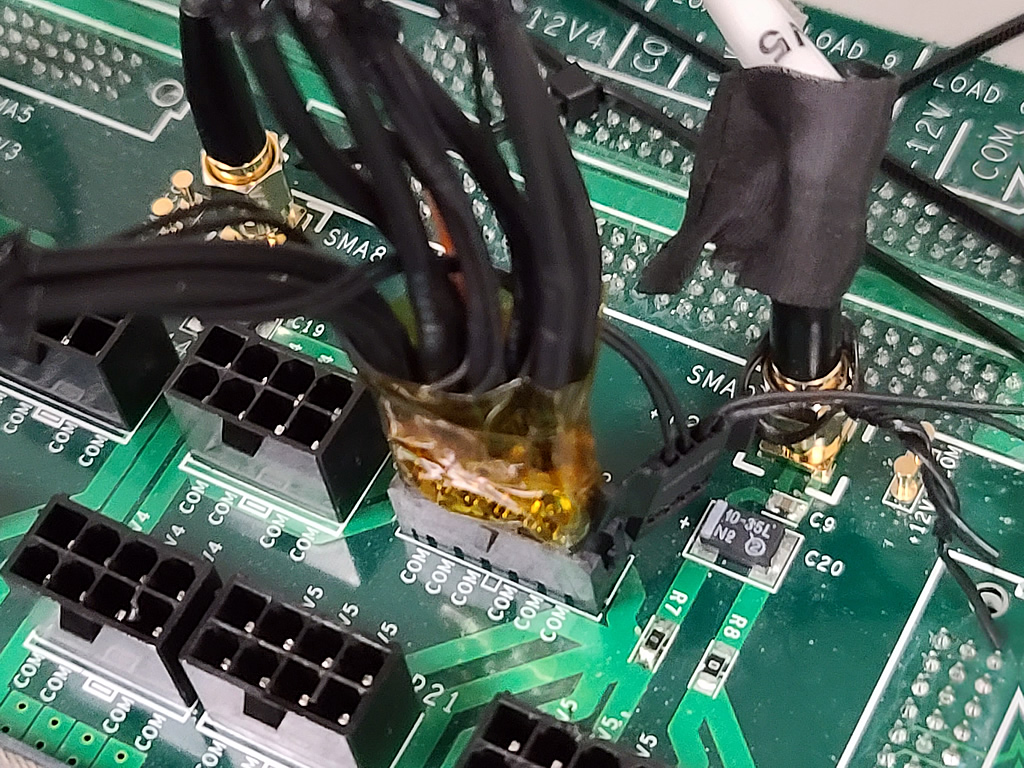

Here's a close up of one of the connectors in the test fixture.

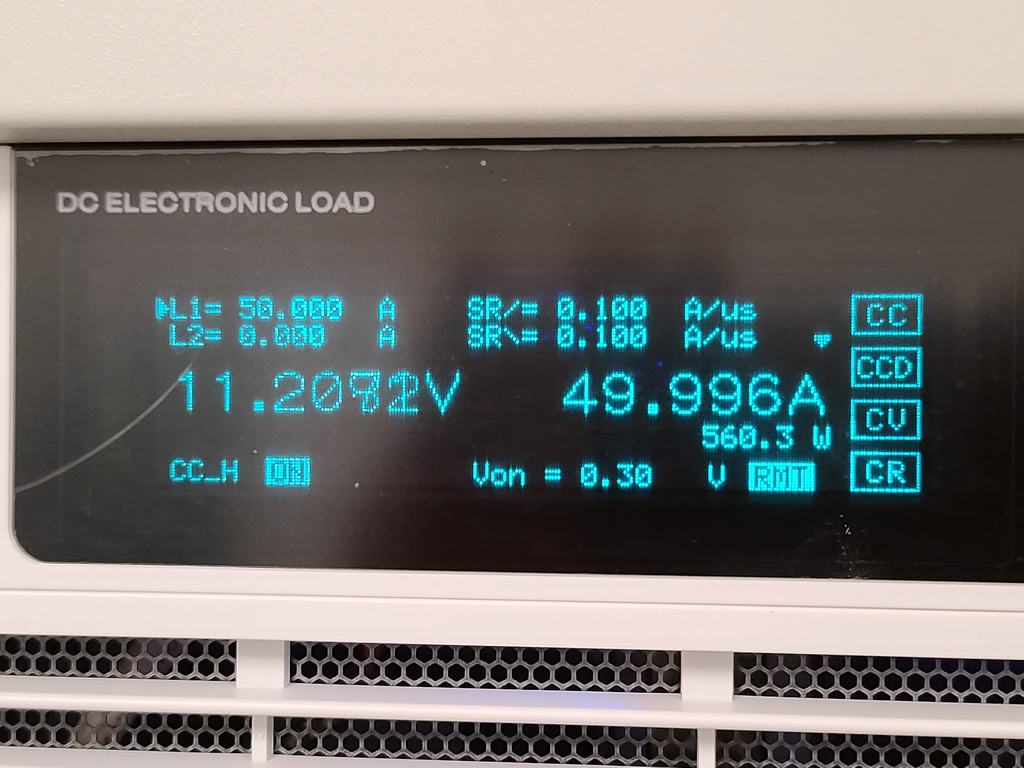

This is our 4kW load not even breaking a swet with a 50A load on the connector.

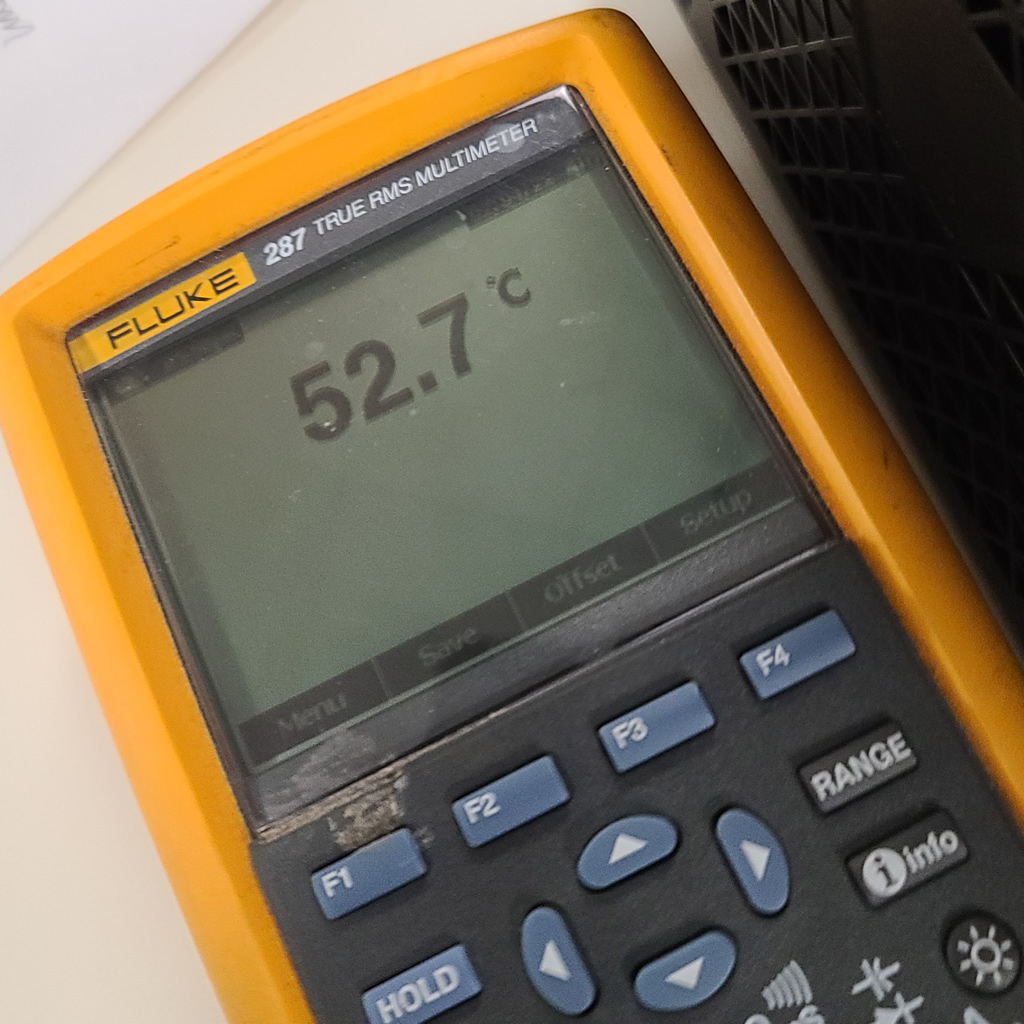

Here's the Fluke. Spoiler alert: 52.7°C is the hottest temperature we saw.

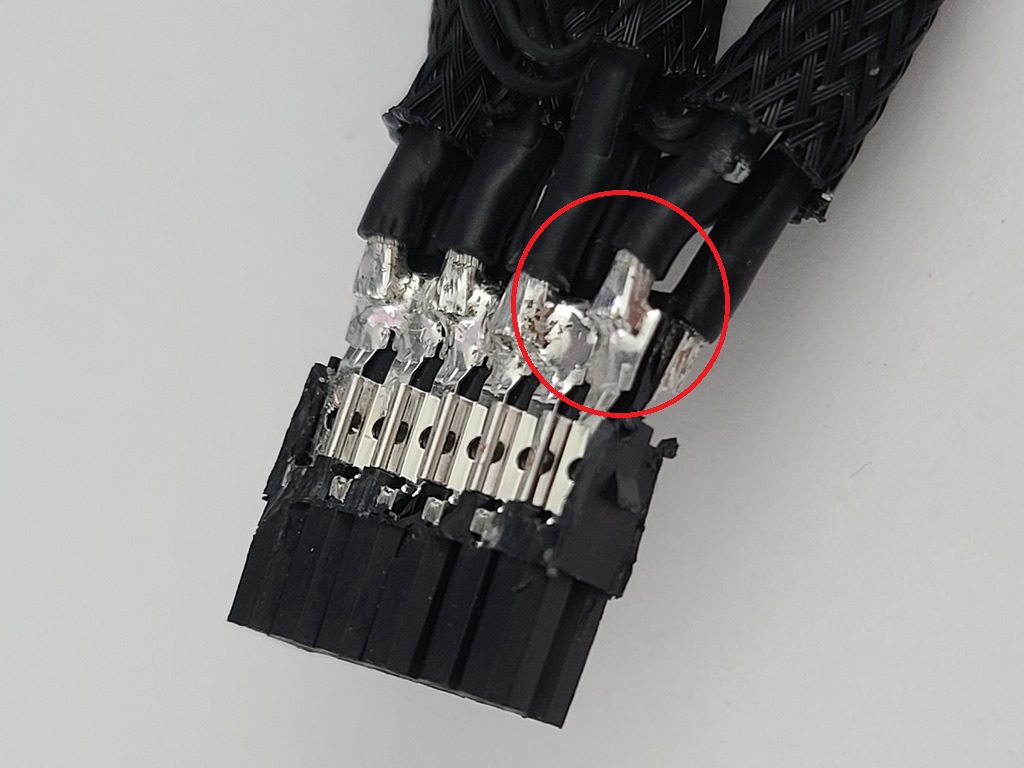

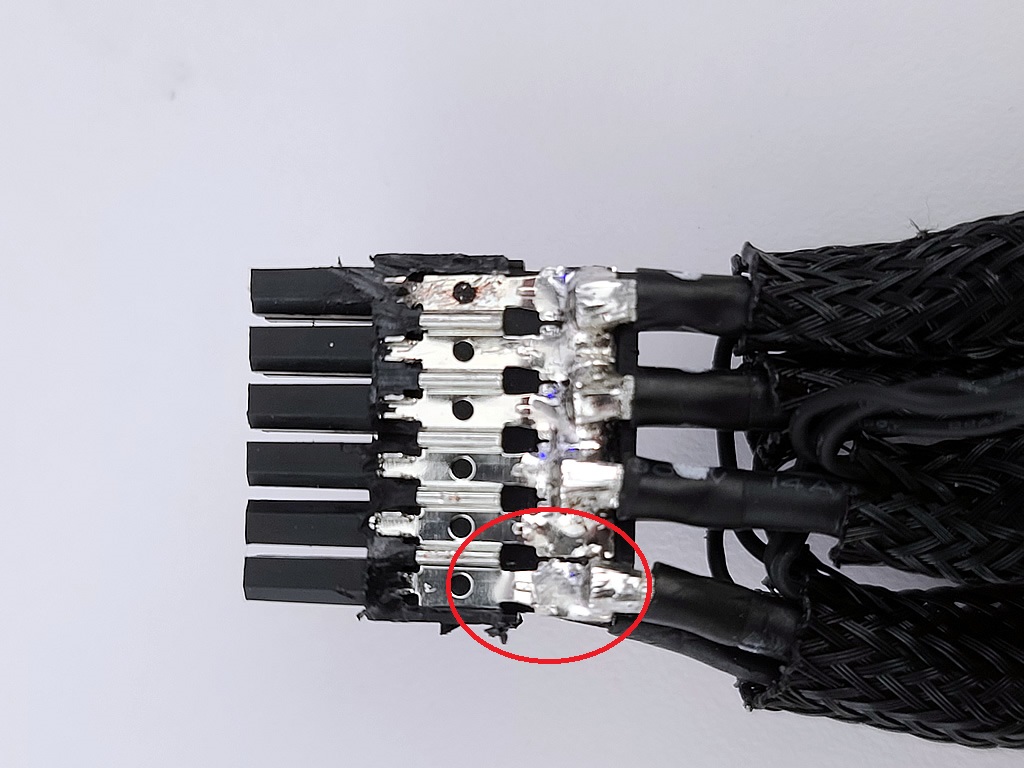

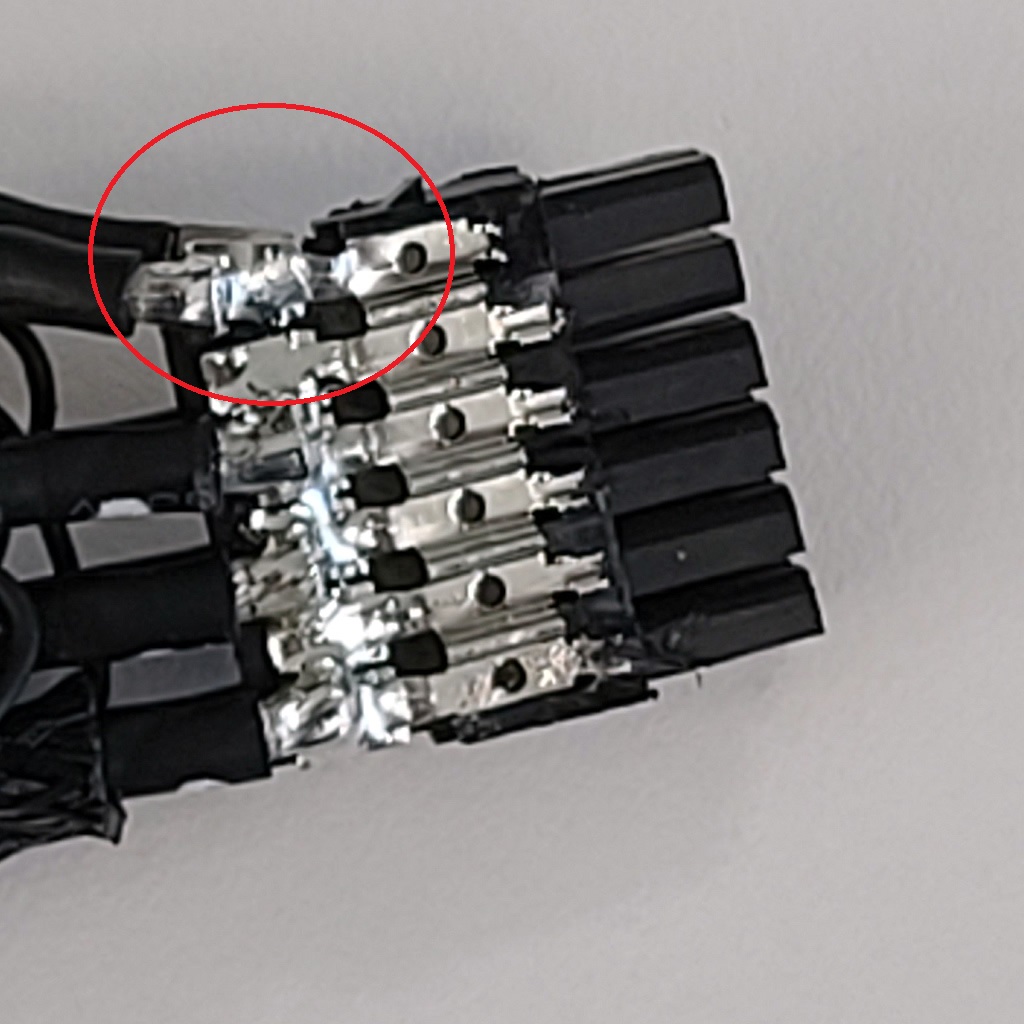

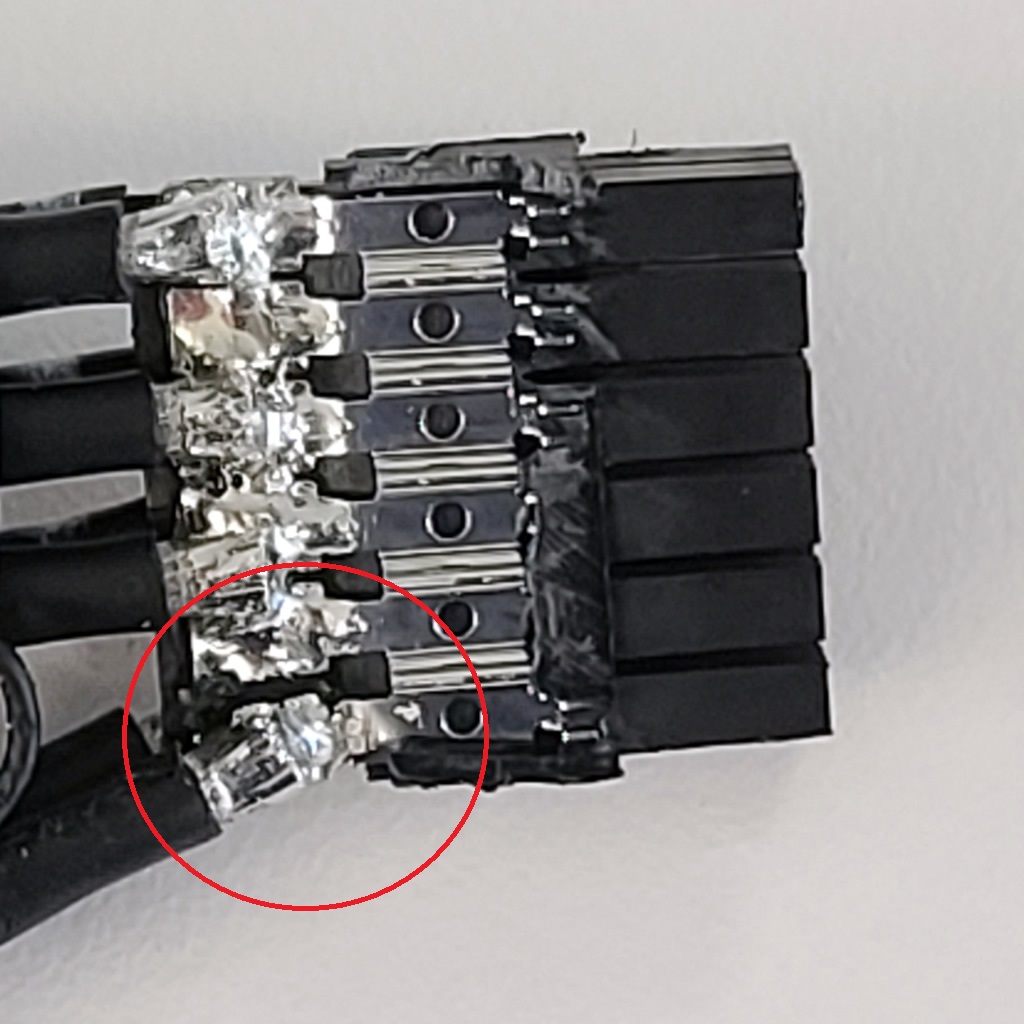

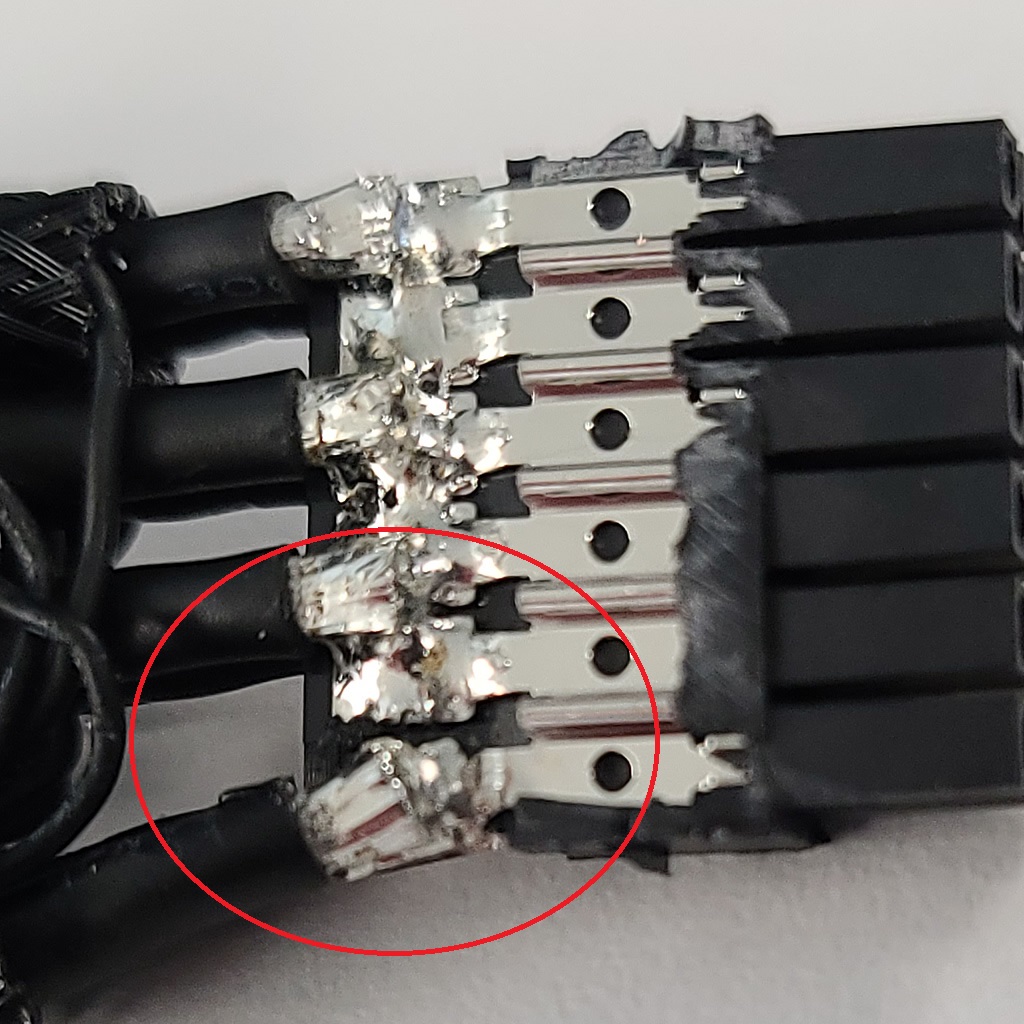

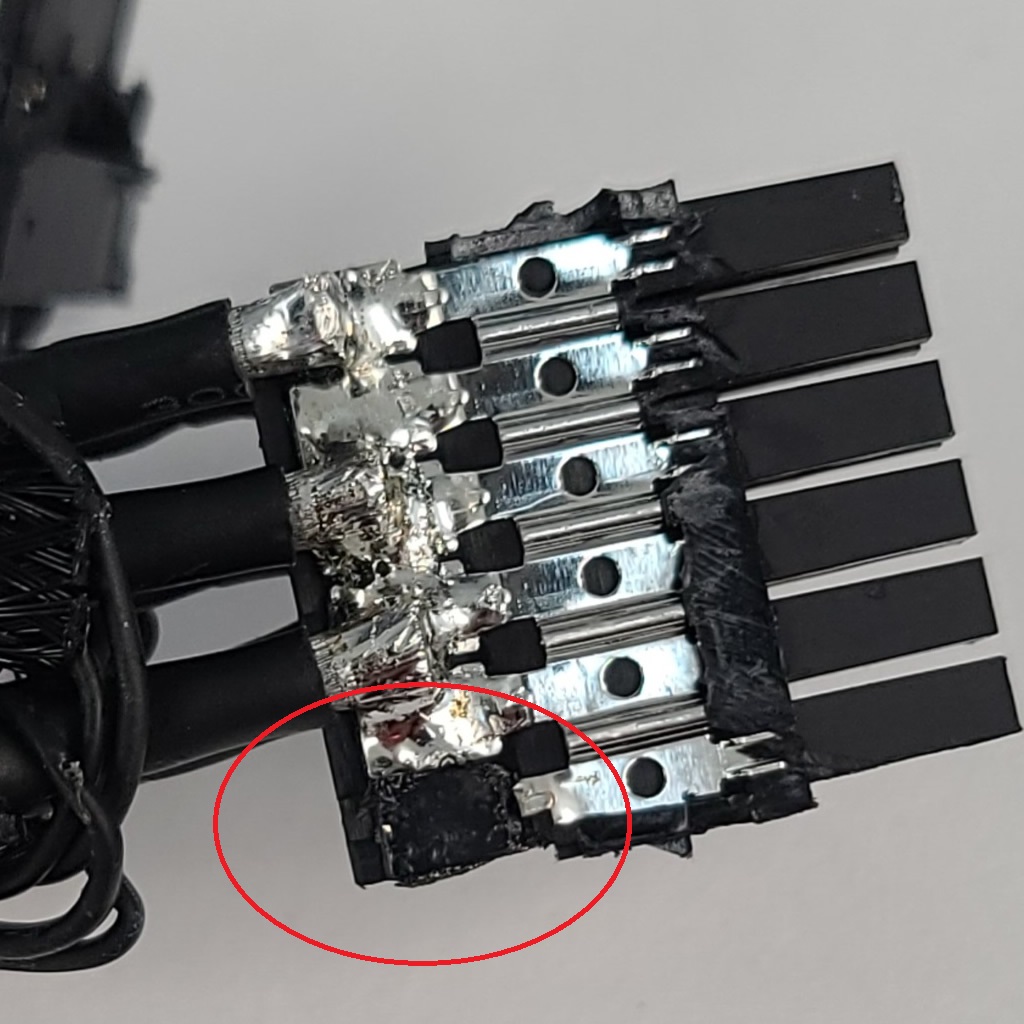

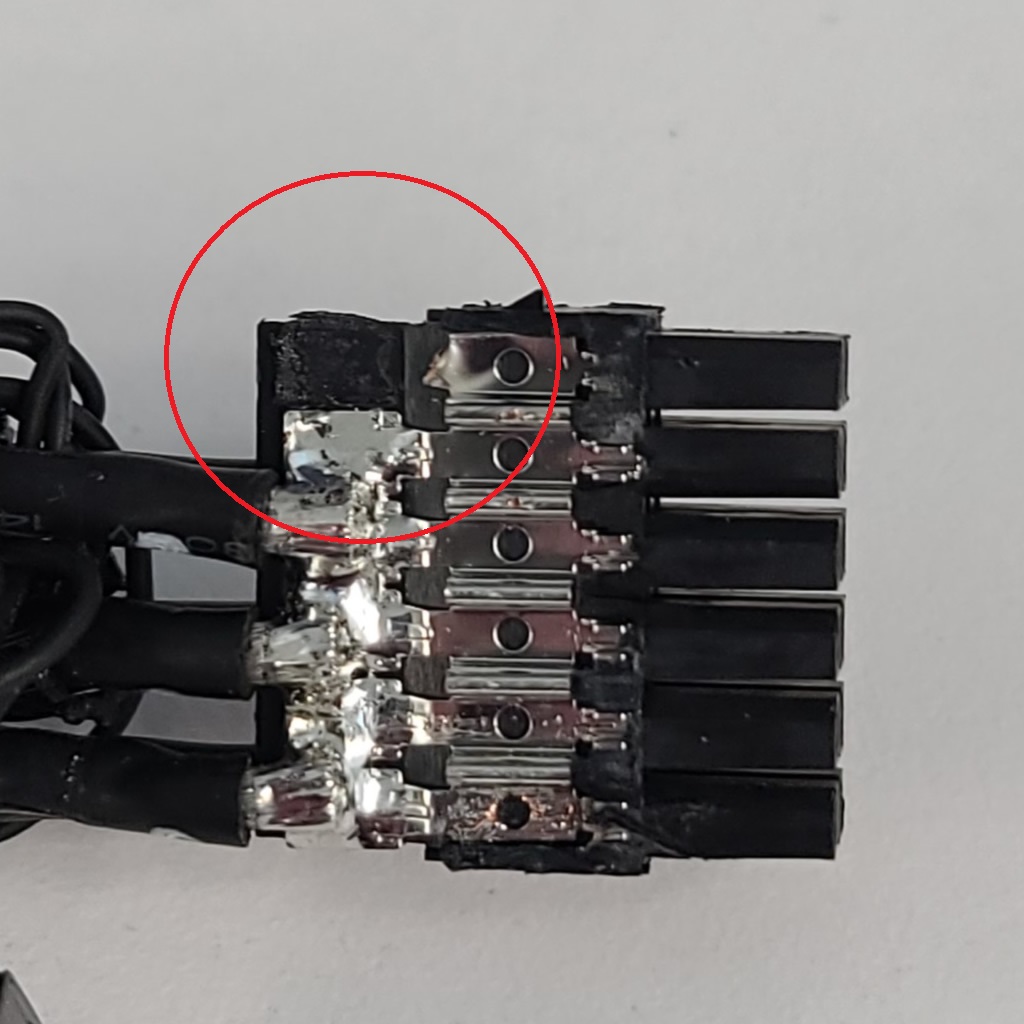

This adapter was the worst of the lot. You can see that one of the wires is barely soldered to the pad compared to the others. Despite this, this connector passed all day testing without any damage to the connector.

I then took this connector, broke it away from the others and gave it a kink. After a full day, this one wasn't damaged either.

I gave this one a good yank too. No issues.

Here, you can see that I actually started to break the terminal. No problems.

Try harder?

Still perfect.

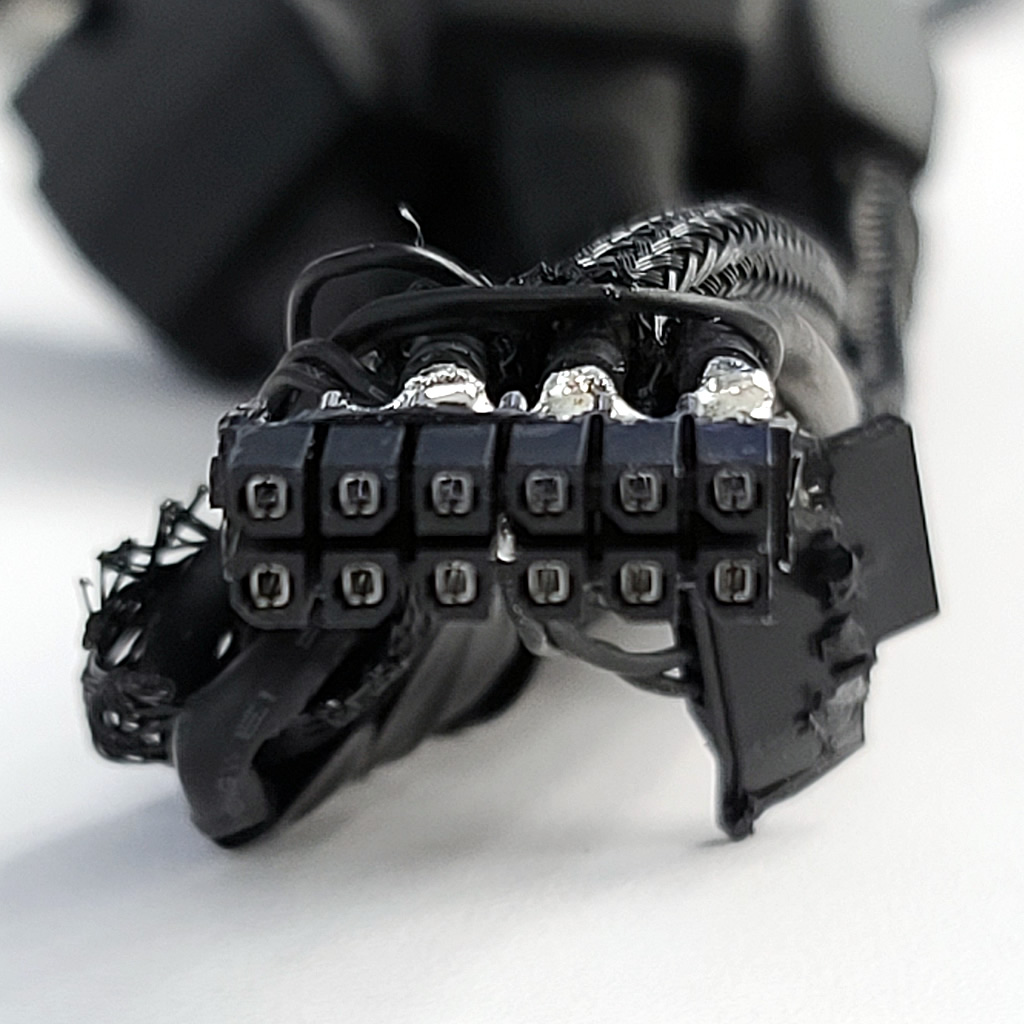

Okay. Fine. I decided to start ripping wires completely off the connector.

This one too!

Still perfect. No melting connectors.

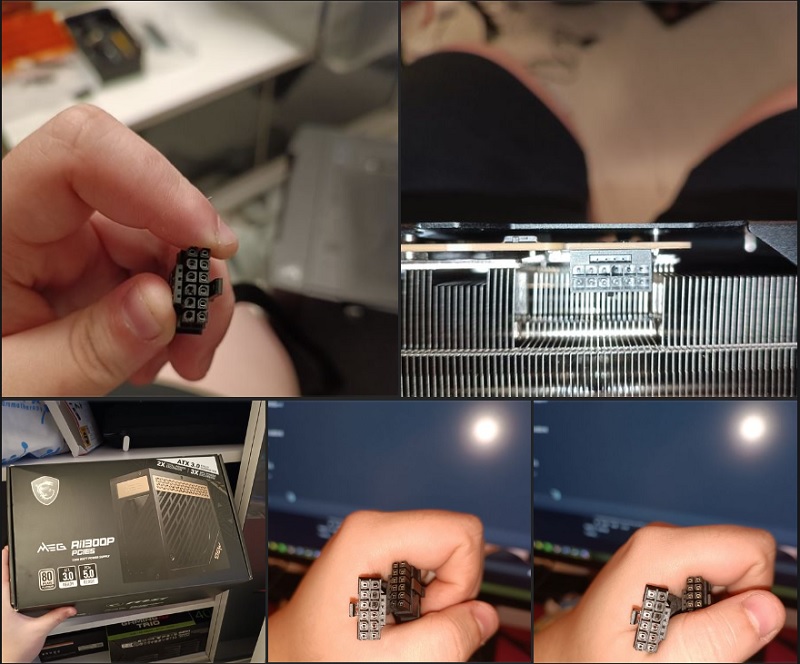

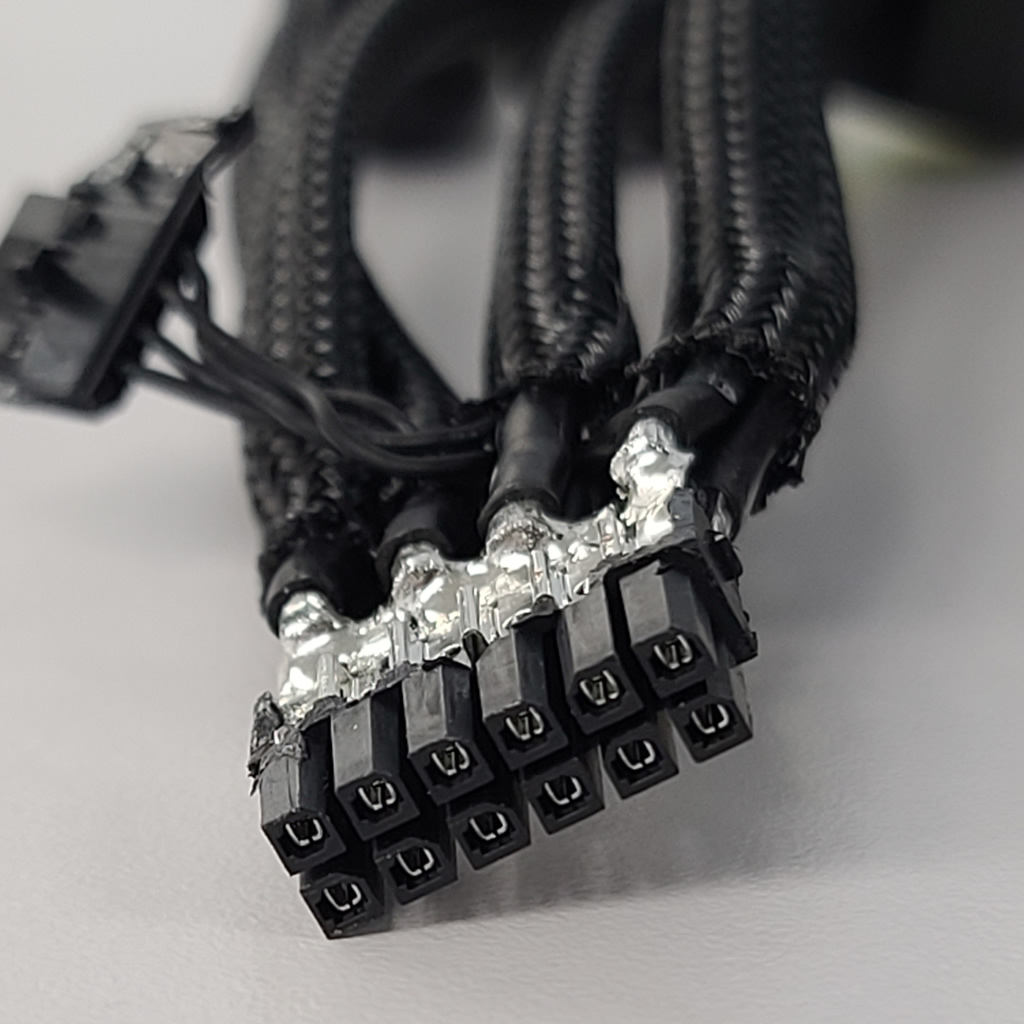

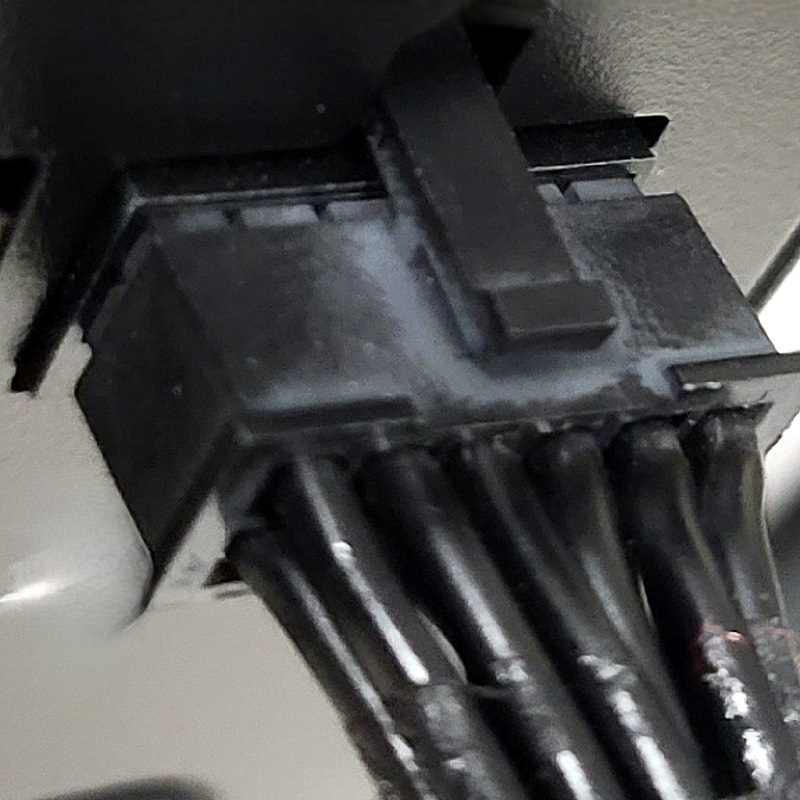

These next two pictures, I'm using a PSU side 12VHPWR connector to illustrate how to tell if a connector is not fully seated. Using a PSU, it's easier for me to take clear pictures (no heatsink in the way) and if I melt the connector, I'm only out a PSU and not a $1500 GPU or the test fixture on my Chroma.....

Here's an example of a 12VHPWR connector that's not plugged all of the way in. You shouldn't be able to see any of the sideband.

Here's the otherside of the 12VHPWR connector that's not plugged all of the way in. You should not be able to see ANY of the terminal housing. Ignore the white powder. That's a byproduct of the flame retardant used so the connector can meet UL's 94 v0 rating.

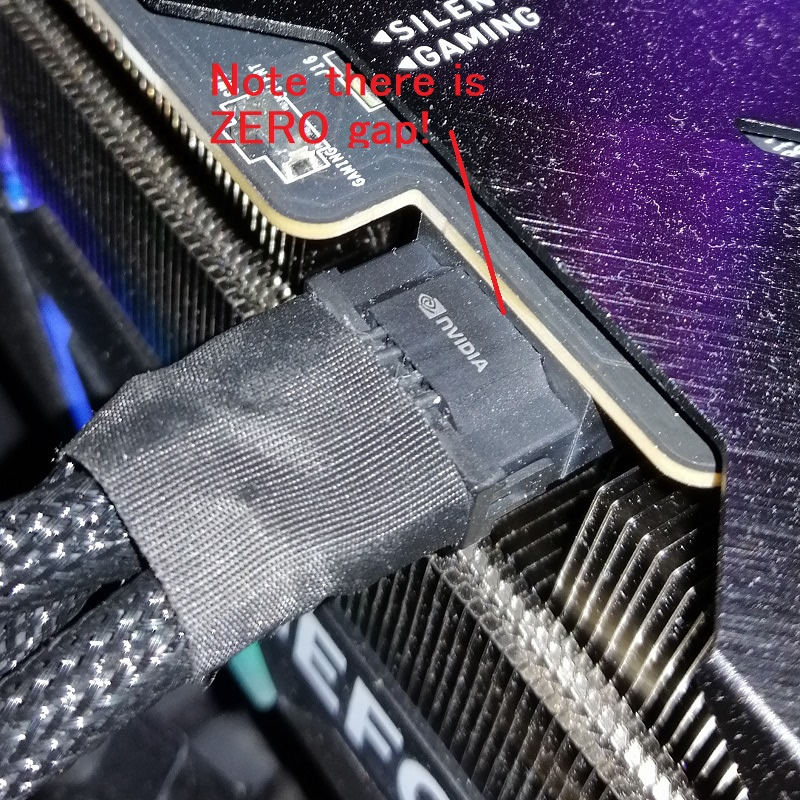

Finally I was able to find some pictures online of users that did and did not have their connectors in all of the way....

This is a correctly installed 12VHPWR connector.

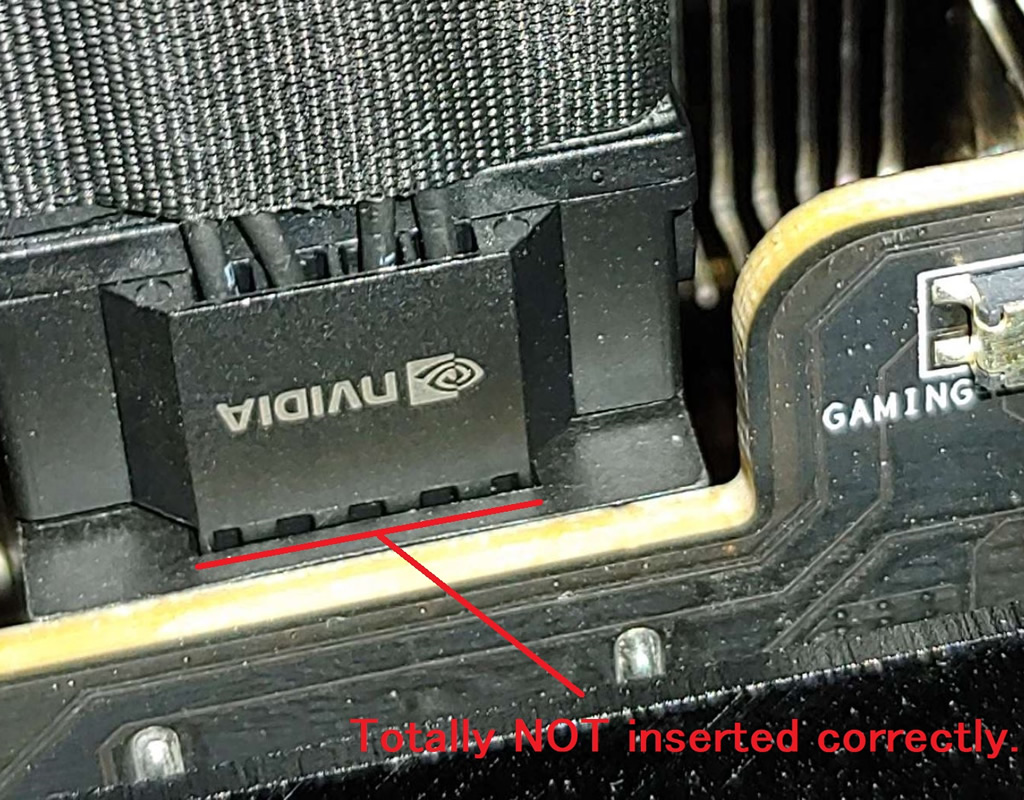

This is NOT correctly installed.

UPDATE (11/4/2022): Woke up this morning to someone posting this:

I believe this leads us to the conclusion that ANY 12VHPWR connector can potentially burn up because ANY of them can be hard to insert. We've likely seen MORE of the adapters burn than we have seen native cables because there are more adapters in peoples' hands than anything else.

Given that the conductor part of the connector is the same as the one used on the 30 Series FE card, it's my thought that this added sideband is preventing full insertion, which in turn causes the high resistance.

In conclusion" It's my opinion that the adapters are fine. You just have to make sure the connector is fully inserted into your card and/or PSU. That said, I will admit that the connectors are VERY DIFFICULT to insert completely. It is easy to think the connector is in all of the way when it's not. But if the retention clip is not engaged, you will be able to pull the connector back out without squeezing the clip. If the connector and retention clip is fully engaged, the card is definitely fully seated.

I would also like to take this opportunity to recommend using dielectric grease (NOT an affiliate link). A $4 investment for a $1500 GPU. As it is said in the "Tin Commandments": Tin contacts need lubrication. Tin contacts need lubrication. I would use at least some dielectric grease on the plastic parts to help them interface. The grease can impact electrical conductivity as much as it can lubricate and prevent corrosion. But since it's dielectric grease, it's not going to hurt if a little bit gets on the terminals because it's not electrically conductive.

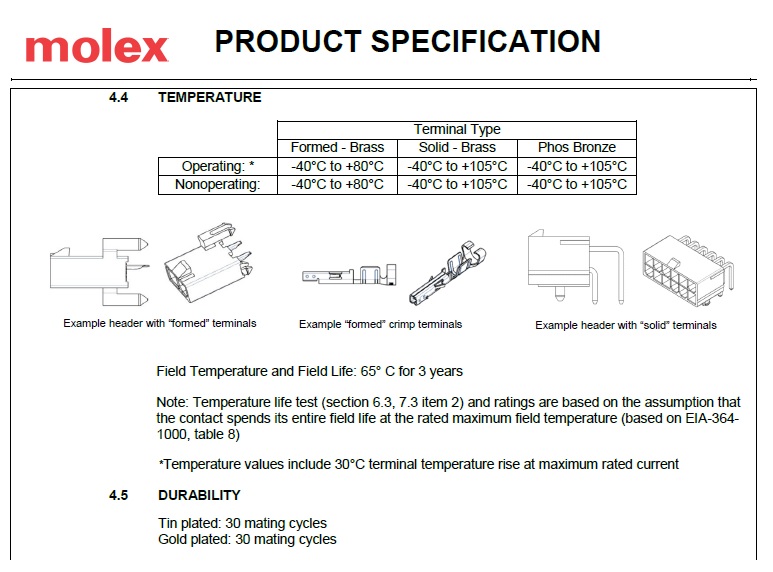

I came to this conclusion when using this particular connector specifically because I found the connector easier and easier to install after X number of cycles. But if I tell someone to instert and remove their connector a number of times until it feels secure and the latch engages, someone is going to bring up the "OMG! It only has 30 mating cycles!!!!!" (for the record, your "old" 8-pin mini-fit jr. connector is also rated at 30 mating cycles). Excess of the grease will certainly "squirt out" and I'm suggesting dielectric because it's non-conductive.

UPDATE 11/6/2022: I've seen a few people recommend others to go out and get gold plated terminals to replace the tin plated terminals. Don't.

The default terminal for 12VHPWR is tin plated brass to avoid galvanic corrosion between gold and tin terminals. Sure... Gold would have been a better plating if you could enforce it. But here we are with tin plated terminals all around.

When you mix gold and tin, you create a galvanic corrosion between the two. Funny story, I learned about galvanic corrosion before I even was into building PCs! When I first worked at a bicycle shop, we would grease the aluminum seatposts before putting them into the steel frames because if we didnt, the post would literally WELD itself into the frame. And, as it is said in the "Tin Commandments" Tin contacts need lubrication. I would use at least some dielectric grease on the plastic parts to help them interface. The grease can impact electrical conductivity as much as it can lubricate and prevent corrosion. But since it's dielectric grease, it's not going to hurt if a little bit gets on the terminals because it's not electrically conductive.

UPDATE 11/6/2022: ModDIY has decided to post a misleading article about the extended sense pin protection on Amphenol's newest connectors (dated 10/31/2022). Their article can be found here.

The extension makes is more difficult to damage the sense wires when inserting and removing the connector.

What makes this post misleading is that it implies two things:

1. By posting the pictures of burnt connector at the bottom of the article, they're implying that this "corrective action" has something to do with this failure. Sense pins do not carry current. And if they're damaged to the point where they don't make connection, the GPU will either run at a lower clock speed or not at all depending on which wires are damaged.

2. It implies that this is a design change exclusive to Amphenol. Have a look at any Corsair, beQuiet or MSI 12VHPWR connector, to name a few, and you'll note they've been using a similar shaped connector long before 10/31/2022.

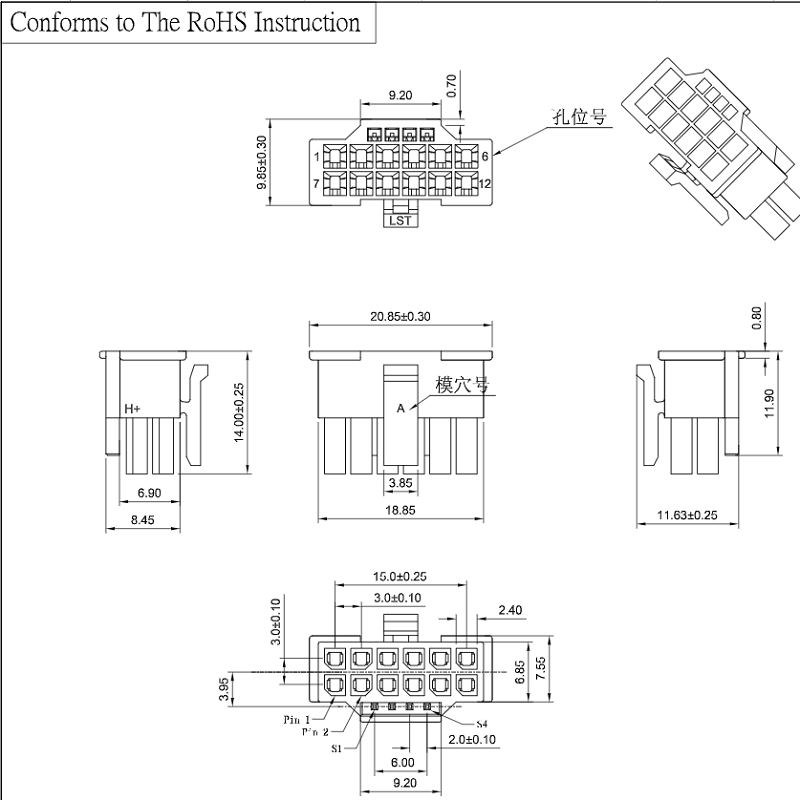

For example, here is a drawing of LST's 12VHPWR connector I have dated 03/16/2022:

So to be clear, this design change DOES NOT prevent melting conductors and DOES NOT make it easier to install or remove the connector. It simply protects the sense pin wires.

UPDATE 11/7/2022: ModDIY has removed the picture of the burning connectors from their article, thus removing the insinuation that damaged sideband wires cause burning conductors.